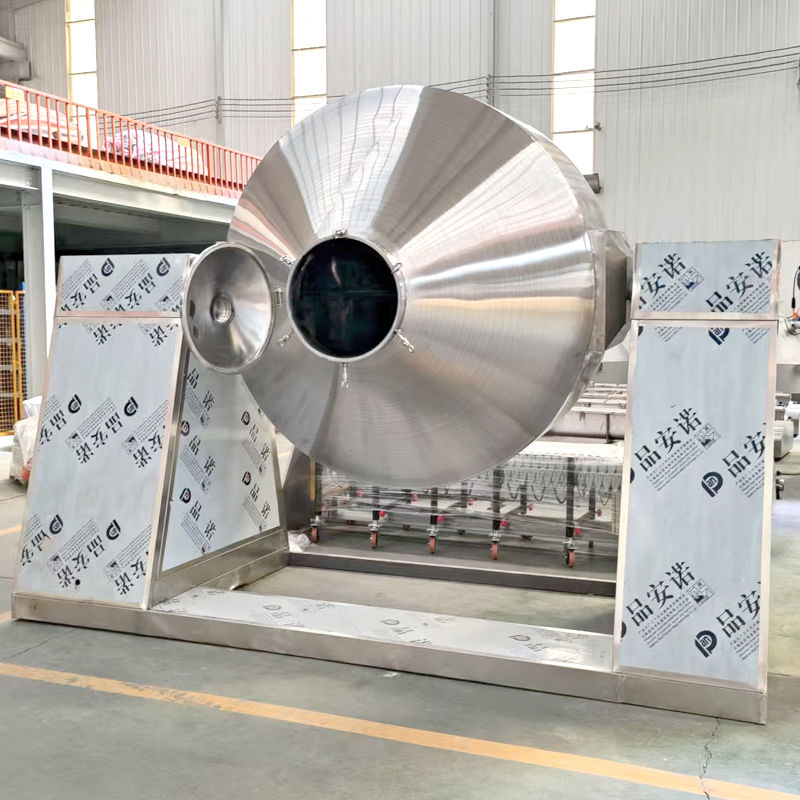

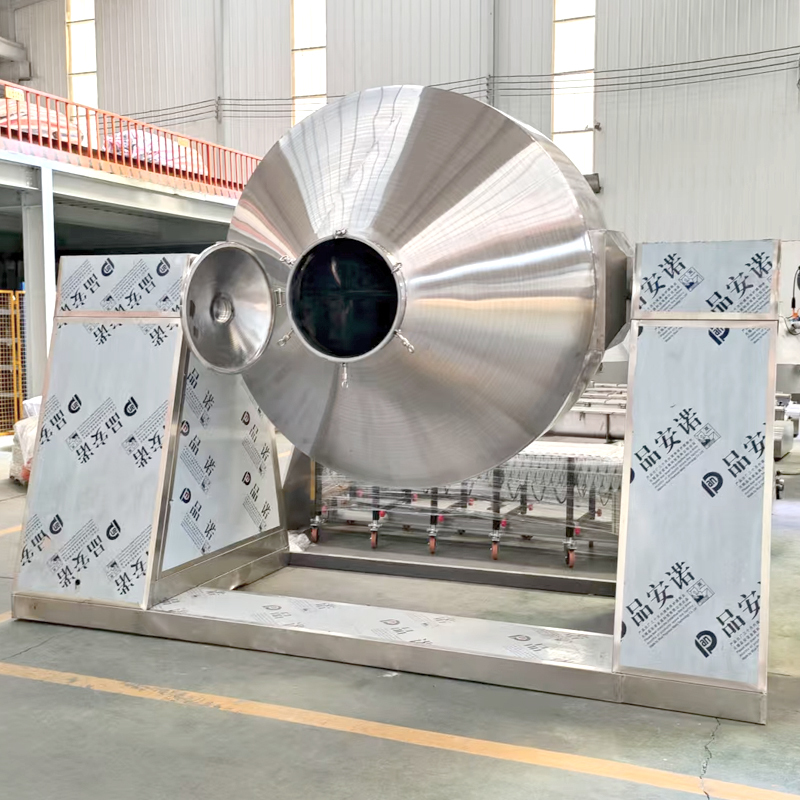

Double Cone Mixer

Product description

The double-cone mixer is an efficient powder mixing equipment widely used in the pharmaceutical, chemical, food and other industries. Its core structure is composed of two symmetrical conical cylinders connected together, and the inner walls of the cylinders are smooth without any dead corners. It features high mixing efficiency, strong adaptability to materials, thorough discharging without residue, simple operation and easy cleaning. It is particularly suitable for production scenarios that require high uniformity of mixing and avoid material contamination.

Working principle

1. Elevating and Descending Effect: When the double-cone cylinder rotates around the horizontal axis, the materials inside the cylinder will be continuously lifted to a certain height as the cylinder rotates. Then, under the influence of gravity, they will freely fall. Due to the height difference, impacts and dispersion occur among the materials, breaking the initial agglomeration state.

2. Convection and Shearing Effect: Due to the symmetry of the double-cone structure, the materials will perform a combined axial and radial motion along the cylinder wall during rotation, forming a convection cycle; at the same time, due to the difference in movement speed in different areas, shear forces are generated, further refining the material particles and promoting mixing.

3. Diffusion and Penetration Effect: During the continuous rotation, elevation, and descent process, the material particles achieve diffusion through continuous position exchanges. Smaller particles will penetrate into the gaps between larger particles, ultimately achieving uniform distribution of various material components at both the macroscopic and microscopic levels.

Product characteristics

High uniformity of mixture: Multi-mechanism synergy, meeting the requirements for high-precision mixing.

Less residue, good cleanliness: No dead corners design reduces material adhesion, thorough discharging, easy cleaning, in line with clean production standards.

High efficiency, low energy consumption: Short mixing cycle, no need for high-power components, low energy consumption and stable operation.

Flexible operation: By adjusting the speed and time, the mixing process can be controlled, suitable for different material requirements.

Application

1. High uniformity of mixture: The conical structure enables the materials to flow freely, reducing stagnation, especially suitable for powders/particles with similar densities. High uniformity of mixture: The conical structure enables the materials to flow freely, reducing stagnation, especially suitable for powders/particles with similar densities. High uniformity of mixture: The conical structure enables the materials to flow freely, reducing stagnation, especially suitable for powders/particles with similar densities.

2. Low residual content: Smooth inner wall + no dead corner design, the residual after discharging is much lower than that of equipment with stirring paddles, suitable for high-value materials.

3. Good sealing performance: The fully enclosed structure reduces dust leakage, meeting the clean production standards of industries such as medicine and food.

4. Simple maintenance: No complex components, low failure rate, and lower maintenance cost than paddle or blade type equipment.

5. Lower energy consumption: Mixed by gravity and rotation, no need for high-power motor, and the operating cost is more economical.

6. Wide applicability: Suitable for drying powders/particles and small amounts of liquid mixing, with little damage to fragile materials.

Product parameter

| Model |

W-300 |

W-500 |

W-1000 |

W-1500 |

W-2500 |

W-4000 |

W-6000 |

W-8000 |

|

Production capacity

(kg/time)

|

150 |

250 |

500 |

750 |

1250 |

2000 |

3000 |

4000 |

|

Full volume

(cubic meter)

|

0.3 |

0.5 |

1 |

1.5 |

2.5 |

4 |

6 |

8 |

|

Mixing time

(min)

|

4-8 |

4-8 |

6-12 |

6-12 |

6-12 |

6-15 |

6-15 |

6-15 |

|

Motor power

(KW)

|

1.1 |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

| Cylinder speed (RPM) |

15 |

15 |

12 |

12 |

12 |

10 |

10 |

10 |

|

Dimension

(L*W*H)

|

1680*650

*1600

|

2080*750

*1900

|

2150*850

*2100

|

2300*1600

*3100

|

2500*1000

*2450

|

2980*1580

*2800

|

3500*1800

*3000

|

3980*2000

*3200

|

| Weight (kg) |

310 |

550 |

800 |

950 |

1650 |

1880 |

2350 |

2680 |

Production Line Diagram

1. Worker release the bag on the dust-free bag dumping station, as there is a dust collector in the machine, so dust fly

2. The sieve machine will remove the lump or big-size material, only allowing smaller size material to flow into the conveying system

3. The vacuum conveyor transports the material to a buffer hopper or a storage hopper, waiting for the mix

4. When you need to mix, the vacuum feeder starts work, transport the material from the hopper to the double cone mixer

5. After mix, the mixed material will be transported to a packing machine, packed according to the set weight, and then sealed the bag

In the system, the entire conveying process is sealed to ensure hygiene and safety.

Detail display

Product display

Packaging & Shipping

Why choose us

About us

Company Profile

We have been specializing in the production of Screening and conveying equipment for 13 years. China's vibrating screen industry top three. And we have done matching and OEM for many large companies. Including the world's top vibrating screen manufacturer, Sweco, USA, we have OEM for his China region. And our products are often exported to Australia, Thailand, Indonesia, New Zealand and other countries.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!